Blogue

An “optical nose” to sniff out dairy farm GHG emission reductions

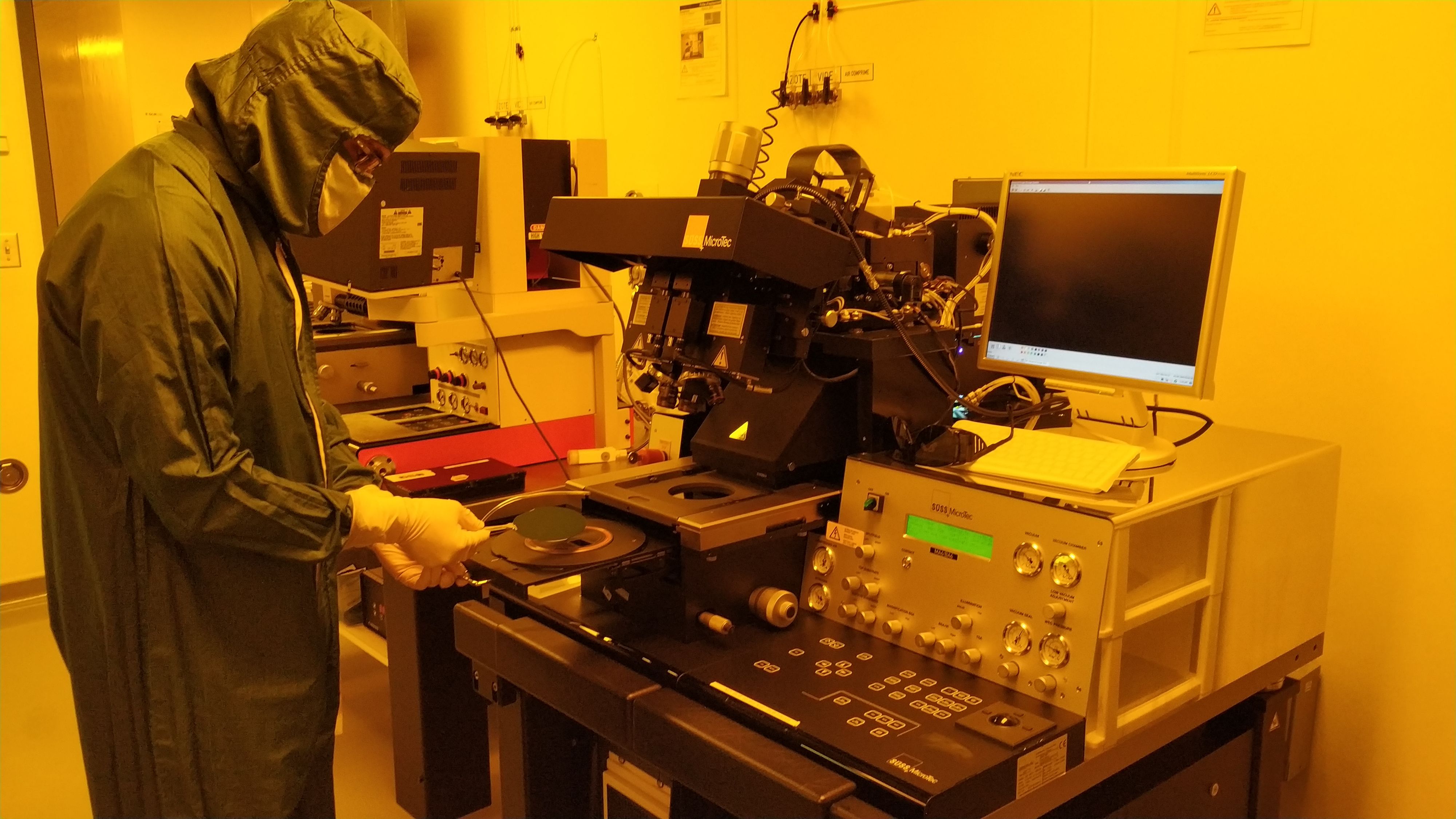

An “optical nose” developed by Yves Alain Peter's team was tested earlier this summer at McGill University's Macdonald Experimental Dairy Farm. (Photo: Marc-Antoine Bianki)

Just like Jeff Bezos and Richard Branson, Yves-Alain Peter's laboratory's “optical nose” will also fly into the stratosphere this summer. Until then, however, you'll find it firmly on the ground with the cows, quite literally. The tool is used to measure methane produced by a dairy farm's bovine denizens, and its long-term goal is to help the industry reduce its greenhouse gas emissions. Methane produces a greenhouse effect 28 times more powerful than carbon dioxide.

The tool itself is a small silicium wafer where a few optical fibers converge, all of which fits on a fingertip. On that wafer are one to four “olfactory cells” which detect and quantify a specific gas.

Welcome to the world of Professor Yves-Alain Peter from Polytechnique Montréal's Department of Engineering Physics, and Director of the Microphotonics Laboratory. In his laboratory in the J-Armand Bombardier pavilion, the researcher and his team are developing a series of sensors capable of discerning molecules floating in the air - using light.

"We don't focus on a specific field of application," explains Professor Peter. “Instead, our mission is to develop a technology."

Thus, his devices could find their place in several spheres of society, from telecommunications and aerospace, to the medical field, including the gas and oil industries. According to the Professor Peter, these sensors could also be adopted by organizations and cities looking to measure air quality.

On the hunt for methane

Pr Yves-Alain Peter (Photo : Sarah Latulippe) Pr Yves-Alain Peter (Photo : Sarah Latulippe) |

In the meantime, the researcher and his team are tackling a very concrete issue: methane emissions originating from dairy farms.

Jurisdictions around the world have not yet regulated the agricultural sector in terms of GHG emissions, yet there are significant potential gains to be made there - in particular by controlling emissions from the dairy and cattle breeding industries.

According to the United Nations' Food and Agriculture Organization (FAO), various livestock farms on the planet generate a little more than 7 gigatonnes of GHGs each year - the equivalent of what the entire planet's cars produce annually. Yes, you read that correctly.

Also according to the FAO, around 44% of these GHG emissions come from methane produced by cattle, a gas generated by the fermentation of food in the stomachs of ruminants like cows.

What's most staggering is that dairy cow and beef cattle methane emissions represent 6-7% of all GHG emissions generated by human activity on Earth, or 1/16 of GHG emissions globally. However, there are strategies to reduce the impact of these industries on our environment.

Some of these emissions could, for example, be reduced by simply changing cow and steer diets, and teams are already working on that aspect. Yet to determine if a diet is working, you first need a tool that can accurately measure the amount of methane a cow produces, which is where Professor Peter's team comes in.

a glance at... the optical nose |

|

When he's not addressing an audience of neophytes like you and me, Professor Peter presents his optical nose as being an “optical microresonator.” Each cell of this technology is made up of an optical fiber that's cut in half in order to sneak in a polymer, whose physical properties change in the presence of a specific gas. To make it work, a laser beam is sent into the optical fiber. When the light passes through the polymer, it's wavelength changes in proportion to the amount of gas that has penetrated the material. In other words, it changes colour! The phenomenon is imperceptible to the naked eye, but can in fact be measured. This is what a sensor located at the very end of the optical fiber does. By using different polymers for each "cell", and by using machine learning, researchers hope to create a real nose capable of discerning and quantifying several gases at the same time. This is what they will try to do later this fall. As part of a project involving the Canadian Space Agency -- the “CAN-SBX Design Challenge” -- this summer, the PolyOrbitre technical society will test analog modules similar to those found in a nanosatellite. On board will also be none other than nose optics developed by Professor Peter's team. These space-destined noses will measure the concentration of carbon dioxide, oxygen, ethylene, and water vapour at various altitudes during a stratospheric balloon trip. |

The advantages of the optical sensor

By using a laser's light as it travels through an optical fiber, the optical nose technology makes it possible to measure gas concentration from a distance. (Photo: Marc-Antoine Bianki) By using a laser's light as it travels through an optical fiber, the optical nose technology makes it possible to measure gas concentration from a distance. (Photo: Marc-Antoine Bianki) |

Earlier this summer, and in collaboration with Lactanet (an organization headed by Canadian dairy producers), the Polytechnique Montréal team travelled to the McGill University's McDonald Experimental Dairy Farm, located in Sainte-Anne-de-Bellevue, with the objective of measuring the quantity of methane produced by cows while they ruminate.

They positioned their optical nose tool a few centimeters from bovine muzzles, because contrary to popular belief, it’s mainly through burps that ruminants release methane into the air. Researchers then compared the precision and reliability of the optical nose against that of an electronic device. This successful experiment enabled Professor Peter's team to put his optical chip to the test - literally and figuratively in the field.

"It was the first time this technology had been taken out of the laboratory," notes Marc-Antoine Bianki, a doctoral student participating in the project.

According to the PhD student, several challenges awaited the team, in particular the integration of the sensor in the barn, but also the dust and humidity therein, to say nothing of cow behaviour. "They seemed curious and were trying to lick the tool," Bianki says.

Once the technology has been fully validated, the researchers would like to use it to test various diets, to identify those that minimize methane production.

As Professor Peter notes, this new technology should find work well, since it has several advantages compared to “electronic noses” which operate using a transistor. “In addition to being much smaller, our sensors are safe and don't heat up because they work with light, not electricity. All they need to work is a laser," he adds.

"So, we could deploy several chips in the same building at a comparable cost - if not lower cost than that of electronic noses."

learn more

Professor Yves-Alain Peter expertise

Microphotonics Laboratory website

Microfabrication Laboratory website

PolyOrbite website

Comments

Commenter

* champs obligatoire