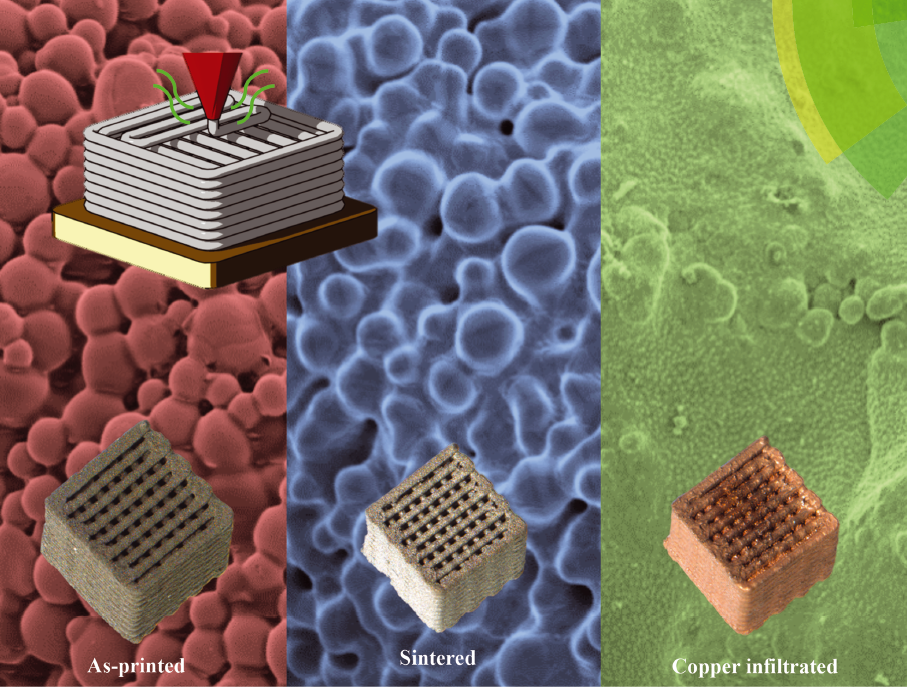

Researchers from the Advanced Composite and Fiber Structures Laboratory developed a new 3D printing method for high-performance metallic structures. This new innovative method relies on three steps:

First, the structure is printed using a highly concentrated metallic ink (metallic load up to 98 wt%) made of highly alloyed steel (HAS), polylactic acid (PLA) and dichloromethane (DCM). Then, the structure is heated to burn the polymer, and sinter the metallic microparticles. Finally, the last step consists in a second heating phase where the structure is covered by a piece of copper. The later will melt, and fill the pores between the steel filaments, thus creating a steel reinforced copper composite structure.

This new method allows the fabrication of high performance metallic pieces with a lower cost than previously existing methods (Selective laser sintering and Selective laser melting). It also allows the fabrication of pieces with complex geometry such as porous, interlocked or even overhung structures.

Publication reference: