Nouvelles

Plastic recycling goes electric: new technology gets a boost

Instead of relying on fossil fuels, chemical processing plants may soon be able to use electrically-generated heat units. Leading the charge is Pyrowave, a company established in 2014 by two Polytechnique Montréal graduates, who today announced a research project in conjunction with Professors Bruno Blais and Jamal Chaouki (Department of Chemical Engineering). The purpose of the research project is to accelerate the deployment of this new technology, by first understanding what happens in a giant microwave reactor like the one made by Pyrowave.

Pyrowave designed and assembled the reactor – similar to a fermentation cask – in its Salaberry-de-Valleyfield pilot-plant. (Photo : Pyrowave)

In order to reduce their carbon footprint, Canadian companies need to rethink how they produce heat. Until now, nearly all industrial chemical processing methods rely on the combustion of fossil fuels, whether to cook or dry food, make concrete, or pour metal.

As a result, the industrial manufacturing and processing sectors generate 14% of Canadian greenhouse gas emissions. In Québec, that percentage climbs even higher to 24%, as was highlighted last year in HEC Montréal’s Portrait des émissions industrielles de GES (in French only) produced by their Chaire de gestion du secteur de l’énergie. Developing industrial technologies that use electricity drastically reduce pollution emissions, provided of course that energy comes from renewable resources – and it’s exactly that technology that Pyrowave is seeking to develop.

From left to right: Jamal Chaouki, Full Professor in the Department of Chemical Engineering; Bruno Blais, Assistant Professor in the Department of Chemical Engineering.

Electrifying the process using micro-waves

The company had already designed and assembled a microwave reactor in its Salaberry-de-Valleyfield pilot-plant. The reactor uses an effective process, using polystyrene degradation to become styrene monomer, all while using an electrical source of energy.

Yet prior to diving into large-scale plastic recycling, Pyrowave wants to first thoroughly understand how reactions occur and evolve within a micro-wave reactor, which is currently something of a mystery. The latter knowledge will then help to optimize reactions, as well as to ensure the safety of the entire process.

Though they might share a name, a microwave reactor has very little in common with the microwave oven sitting in our kitchens. Conventional microwaves heat up food by making water molecules in food vibrate, which in turn produces heat that cooks food. Polystyrene requires an intermediary in order to capture the mircowave energy and to depolymerize – namely silicon carbide (SiC) particles. When they absorb microwave energy, SiC particles behave like sharp knives, one by one removing styrene molecules located at the ends of polymer chains. All the reactions operate without oxygen, a process called pyrolysis, which inspired the name of company.

Yet, how does one disperse SiC particles and melted polystyrene in the reactor, so that heat is distributed homogenously? Also, how does one ensure that the reaction occurs in optimal conditions throughout the polystyrene to styrene transformation? Those are but two (of many) questions that Professor Bruno Blais hopes to answer.

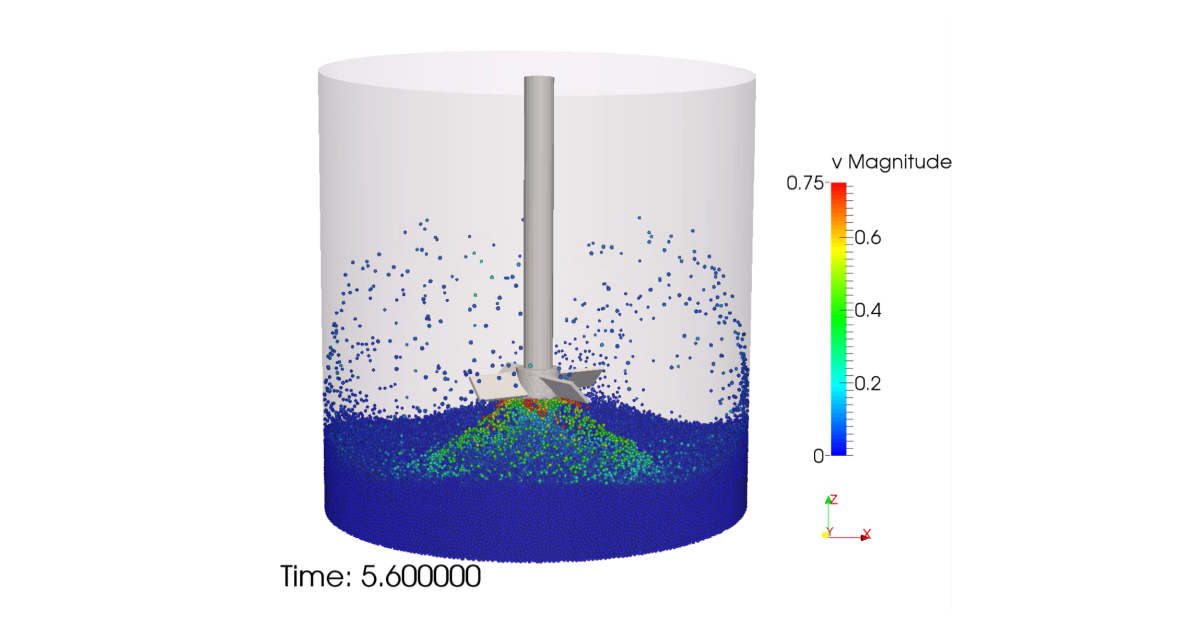

A specialist in fluid mechanics and granular flows, Professor Blais, along with his team, will perform a series of computer-generated simulations to establish numerical models that can predict how heat dissipates in the reactor, and how reactor content is partitioned and transformed throughout the reaction process.

“At the moment, we don’t really know how particles are distributed in the reactor, nor do we know how they absorb heat. It’s truly a mystery,” explains Professor Blais.

Finding out that information will enable the polystyrene degradation reaction process to be optimized, and will also ensure that the entire process is safe, adds the Polytechnique researcher. “Exposing metal particles to microwaves is playing with fire to a certain degree. At all costs, you need to avoid creating electric arcs by ensuring particles are far enough away from each other,” Blais adds.

Professor Bruno Blais’s team will perform a series of simulations to better understand the various components that interact with micro-waves, inside a reactor.

Tracking particles at Polytechnique

To uncover the mysteries of what’s happening in the reactor, the team of researchers will first undertake a tracking experiment. By following the movement of radioactive particles in the tiny reactor in Professor Jamal Chaouki’s lab, researchers will obtain data that will inform the simulations that Professor Blais’ team will complete.

Over the project’s four-year mandate, the group will also test degradation processes for other types of plastic – and that’s just the beginning. Professor Blais states that other industrial processes that require temperatures as high as 500 to 1 000 degrees Celcius may also eventually be electrified. Namely, Blais suggests using microwave reactors to complete biomethanization and drying processes.

“Microwaves are an exceptional technology that remains seriously underused. Their main quality is that they add heat at a volume, instead of adding heat to surfaces, which is what conventional ovens do,” explains Professor Blais.

By the conclusion of the research project, Pyrowave hopes to demonstrate that their electric energy method can replace thermal plastic transformation processes that currently use fossil fuel energy. The Natural Sciences and Engineering Research Council of Canada (NSERC) is supporting the project with an overall grant of $280,000, an amount which includes an investment in Pyrowave of approximately $100,000.

Pyrowave

Founded by Jocelyn Doucet, Jean-Philippe Laviolette (both of whom earned PhDs at Polytechnique Montréal), and by Professor Jamal Chaouki, Pyrowave is a pioneer of chemical recycling using microwaves, referred to by its patented technology of “catalytic depolymerization via high-strength microwaves,” which according to the company’s website, is the most advanced of its kind in the world.

The company intends to use this process to produce recycled styrene intended for the manufacture of synthetic rubber. Among its investors, Pyrowave has attracted tire manufacturer Michelin as of last April, as well as European venture capital company Sofinnova Partners and Québec investment fund Ecofuel.

Learn more

Professor Jamal Chaouki's expertise

Professor Bruno Blais's expertise

Pyrowave website

National Sciences and Engineering Research Council of Canada (NSERC) website