Blogue

Cloning a power plant… in a computer?

In the not-too-distant future, each turbine-generator group linked to hydropower plants could have its own digital twin, to assess in real-time how quickly its components wear down. This is the Daniel-Johnson Dam, linked to the Manic-5 Generating Station. (Photo : Martin Primeau)

In the not-too-distant future, each turbine-generator group linked to hydropower plants could have its own digital twin, to assess in real-time how quickly its components wear down. This is the Daniel-Johnson Dam, linked to the Manic-5 Generating Station. (Photo : Martin Primeau)

In Québec's hydroelectric power plants, routines are set to change, as turbines designed to operate at full throttle will sometimes idle. How will these changes affect part wear and equipment life? A team from Polytechnique Montréal is working to figure it all out – and they might have found the solution in a digital twin.

Every second, electricity providers face the daunting challenge of balancing electricity supply with demand on their grids. While the demand for electricity fluctuates throughout the day without any intervention, production has always been controllable and relatively stable in Québec thanks to hydroelectricity.

However, the situation is changing.

How come? Well, Hydro-Québec has been integrating new energy sources into its network for a number of years. In addition to biomass (cogeneration) and wind power, the provincial electricity supplier now includes solar energy in its network. This diversification creates some challenges for system operators; hydropower production is stable from day to day, but the same cannot be said of energy generated by the wind or the sun.

So? In order to balance network supply and demand, hydroelectric plants are used as valves of a sort, and for example, open valves to adjust alternator power output.

The problem is, that water turbines were designed to operate at an optimal flow rate 24 hours a day - not dynamically. Reducing the volume of water delivered to them changes the forces at work. Turbulence that generates vibrations could accelerate the wear of the parts and force early maintenance operations.

How does one ensure that the equipment isn't shut down for no reason? A team at Polytechnique Montréal is working on a potential solution by creating digital twins of systems similar to those found in turbine-generator units.

Virtual clones

Professor Frédérick Gosselin

(Photo : Thierry du Bois)

|

"Digital twin" is sometimes overused, but in reference to this project, it fits the bill to a 't'.

"The idea is to combine data obtained in real time with a simulation tool," says Professor Frédérick Gosselin from Polytechnique Montréal’s Department of Mechanical Engineering, and the project's leader. The esteemed team also includes Hydro-Québec, and Montréal-based Maya HTT, a company who develops simulation software for the industry. "The objective is not to improve the efficiency of turbines, but to above all to extend the life of the equipment."

In Hydro-Québec's power plants, each turbine-generator unit is equipped with a series of sensors that continuously record data of all kinds, from the volumes of water circulating, to the degree that the value is open, via pressure and vibration data at various locations.

"Hydro-Québec has been gathering this data for several years, and it's information that shows what happens when systems are operating normally. If a system has never had a catastrophic failure, it's hard to know what its limits are because we don't have data about that," notes the Professor.

By developing an artificial intelligence tool that relies on basic physics equations - known as Physics Informed Neural Networks (PINNs) - the Polytechnique professor and researcher hopes to offer a simulation solution capable of identifying wear limits, and which better predicts part wear.

In the short term, this kind of turbine-generator group simulation tool can be combined with the real-time data captured on that equipment to create a bona fide digital twin. The computer tool would then be a clone. "With the clone, we can then test various scenarios and project ourselves several days or weeks into the future to predict equipment condition if we use it one way, or in another way," adds Gosselin.

The operation can then be repeated for each Hydro-Québec turbine-generator group in order to create a digital twin for each unit. “They're all different machines, so you can't take data from one system and apply it directly to another.”

Ultimately, this will permit optimal maintenance operations planning on the systems. "Hydro-Québec's cost isn't in repairing a system, its in having to shut it down. If you can predict the optimal time to perform maintenance on all equipment with sensors, you're in great shape,” says Gosselin.

team work... to the rescue |

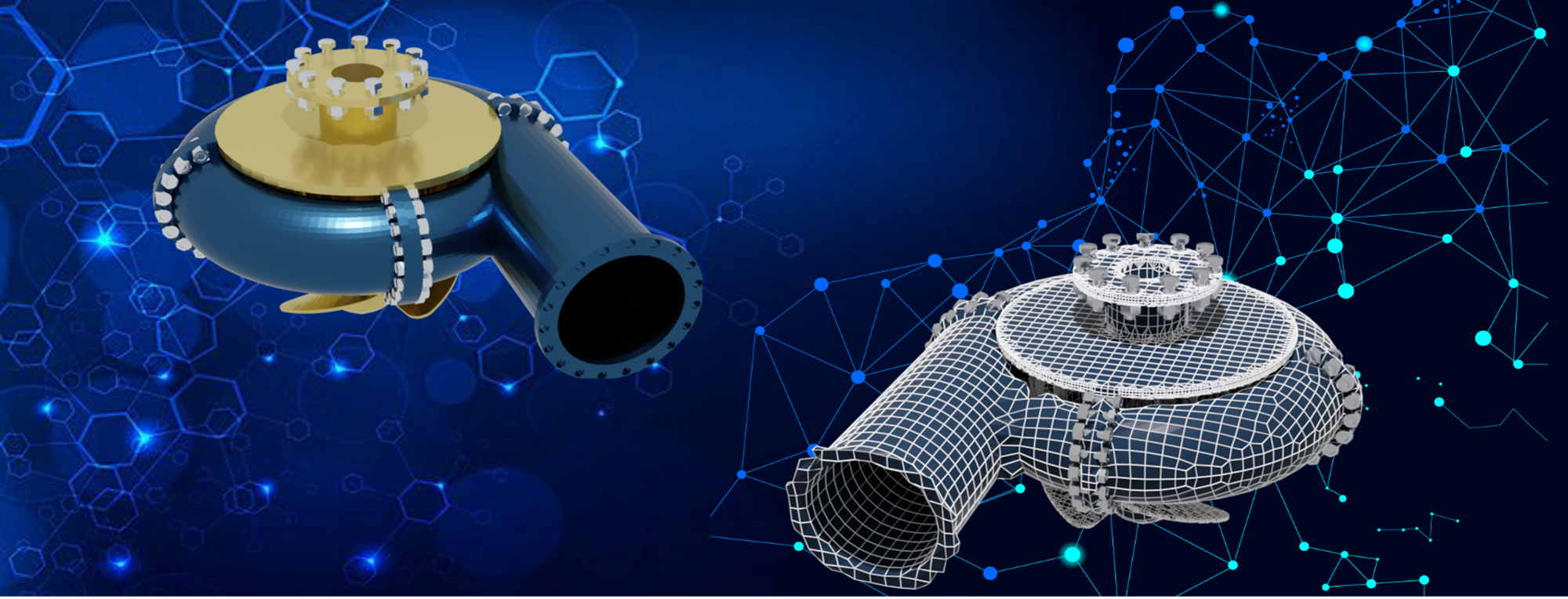

A representation of a real turbine (left) and its digital twin (right) (Credit : Sima Rishmawi) A representation of a real turbine (left) and its digital twin (right) (Credit : Sima Rishmawi)

To complete the project, Frédérick Gosselin's team is working on two fronts. In order to design "reduced-order models" - models that are simplified as much as possible to represent the vibrations of a rotating machine, for example - three PhD students, Sima Rishmawi, Mohammed Abda, and Lucas Berthet - are developing methods by combining neural networks and traditional physics simulations. The above project is supported by the work of two master's students, Morgan Demenois and Souheil Serroud, who have created and instrumented test benches to simulate certain types of vibrations and dynamic behaviours observed on industrial equipment. "These experimental setups will be used to test and validate PhD students' methods," explains Professor Gosselin. "Eventually, we'll be able to run the reduced-order models in a loop by feeding them data from the real system. By doing that, we'll get a real digital twin that behaves in the simulation exactly, as the physical twin does." |

learn more

Professor Frédérick Gosselin expertise

Department of Mechanical Engineering website

Professor Gosselin's IVADO presentation (in french): AI and Mechanical Engineering

Comments

Commenter

* champs obligatoire