Nouvelles

A liquid pixel projector to treat surfaces with increased accuracy

It’s an innovation that could accelerate the completion of biochemical and biological tests - in addition offering entirely new vistas to researchers. A Polytechnique Montréal team recently unveiled its "pixelated chemical display", a kind of miniature liquid projector that permits dozens of experiments to be performed simultaneously. Researchers introduced and discussed their innovation in the most recent edition of the journal “Proceedings from the National Academy of Sciences of the United States of America (PNAS).”

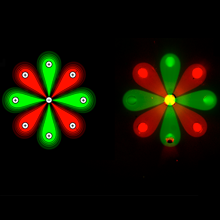

By circulating red or green fluorophores on the surface of the display, Thomas Gervais's team gave a little nod to their alma mater in their article.

Over the past 20 years, the field of biomedical research has made giant leaps by miniaturizing tools and automating certain operations via the use of robots. A test once performed by hand in a plastic test tube or well, can now be completed in one of the many test wells in a hand-held plastic plate that can accommodate 6, 96, or even 1,536 indentations!

However, there is a catch: some things, such as rinsing a well or adding and removing a reagent, can be tedious - even for a robot. Further, these operations must be carried out in a series or in a certain sequence, which prolongs the overall procedure.

"It’s striking to realize that in over 20 years of robotization innovation in the handling of liquids in laboratories, that robots are still only repeating human arm movement. Basically, they robotize the movement of a lab technician – so, there is definitely room for improvement," explains Professor Thomas Gervais, from Polytechnique Montreal’s Department of Engineering Physics, and the article’s primary author.

The innovation that Gervais’ team has just introduced would help circumvent such problems.

Microfluidics as an alternative

In their article entitled "Pixel-based open-space microfluidics for versatile surface processing", researchers presented the prowess of a device called "pixelated chemical display” - which is capable of creating up to 144 independent chemical pixels over an area of just 1 cm2.

A display generates each pixel independently via a series of openings connected to a tubing network. These openings inject or take in liquids, creating a flow that serves to generate each chemical pixel when this display is brought closer to a surface to be processed.

A display generates each colored pixel on its surface via a series of openings (gray dots) that are connected to a tube network, where liquids are injected or aspirated. Rather than mixing, liquids repel each other and create pixels. All of this is due to an amazing property of liquid flow on a microscopic scale.

"It's a completely different approach to handling fluids, which breaks out of the well-and-pipette paradigm. The displays allow reagents to flow into dozens - if not hundreds - of adjacent areas," explains Professor Gervais.

The Polytechnique team is taking advantage of a peculiarity inherent to microscopic-scale liquid physics, adds the Professor. "Such an approach could never work on a macroscopic scale; in those circumstances, the fluids under this device would mix with each other. Yet on a microscopic scale, fluids like water have the fundamental property of moving without any turbulence and therefore mixing very, very slowly," notes Gervais.

According to Thomas Gervais, such an approach will generate test areas on any flat surface, without the need for pits or other physical shapes or indentations. This strategy will also allow the chemical composition of each pixel to vary independently over time, which opens the door to experiment automation.

Several devices based on the continuous flow of fluids on surfaces have already been developed, but the one put forward by the Polytechnique Montreal team is the first to suggest the possibility of a massive parallelization of experiments. “Our approach is modular. Just as a computer screen could be created with different sizes and numbers of pixels, our chemical displays are based on pixels that can be repeated to achieve the number of test areas and the desired size," explains Professor Gervais.

Full Professor Thomas Gervais, Department of Engineering Physics.

In a previous article, the group demonstrated the possibility of using a similar approach to automate immunoassays. During that experiment, researchers were more interested in surface treatment, by demonstrating that it was possible to use their display as if it were a dynamic stamp, that could be used to transfer proteins to a surface at a specific point. determined. At the time, the group also demonstrated the usefulness of its flexible electronics approach by depositing silver circuits on plastic films.

“These are two completely different experiments which clearly demonstrate the flexibility of our technology,” notes Thomas Gervais. He cites that the reconfigurable chemical display could benefit the life sciences industry in a host of applications: “For example, we could test different conditions directly on a cell culture in a Petri dish, or, test different reagents on a tissue or a biopsy,” says the Polytechnique Montréal researcher.

Learn more

Article published in the PNAS journal

Professor Thomas Gervais’ expertise

Department of Engineering Physics website