Research Webzine

Fibres with the strength of spider silk

Professors Frédérick Gosselin and Daniel Therriault, Department of Mechanical Engineering

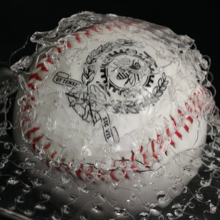

It’s between three and eight microns in diameter but five to ten times stronger than steel or Kevlar: spider silk is an exceptional material. Just imagine all we could build with a fibre that has those properties!

Now we can do more than just imagine, thanks to the work by Professors Frédérick Gosselin and Daniel Therriault. These two researchers have succeeded in producing an ultra-strong polymer fibre inspired from the structure of spider silk. The latter owes its tenacity – that is, its ability to absorb a great deal of energy before breaking – to the unique molecular structure of the proteinacious material it is made of.

The silk coils around itself like a spring, with each loop bound to the next by sacrificial bonds. These are chemical connections that break before the main structure’s molecular chain ruptures when you pull on the silk. This mechanical origin is what piqued the interest of these two researchers at Polytechnique’s Laboratory for Multiscale Mechanics.

Their project involves manufacturing microstructured fibres by pouring a filament of viscous polymeric solution towards a sub-layer that moves at a certain speed. The filament forms a series of loops, kind of like when you pour a thread of honey onto a piece of toast. Depending on the instability determined by the way the fluid runs, the fibre presents a particular geometry. It forms regular periodic patterns, and bonds to itself with sacrificial bonds. The fibre then solidifies as the solvent evaporates. It takes a pull with a strong energy output on the resulting fibre to succeed in breaking the sacrificial bonds.

These researchers think that one day, there will certainly be composites obtained by weaving together tough fibres of the type they are currently developing. Such composites could, for example, make it possible to manufacture new safer and lighter casings for aircraft engines, which would prevent debris from dispersing in case of explosion. Many other applications can be foreseen, from surgical devices to bulletproof clothing to vehicle parts.

Article published in Advanced Materials