| Advanced manufacturing of fiber-reinforced polymer composites Presently, as a research associate at Polytechnique Montreal, I am helping to coordinate a large-collaborative project on advanced manufacturing of aerospace composites featuring high mechanical and acoustic performances with Safran S.A., France. This project covers materials design and characterization to manufacturing of high performance aerospace structures. R. Farahani |

3D printing of composites (tridi.com.tr) |

| Design and Formulate different HTRP materials reinforced CF We develop and evaluate the mechanical properties of composites based on high temperature resistant polymers (HTRP) materials and carbon fibers (CF). The optimization of processing parameters and the 3D printability are studied. A. Diouf-Lewis |

SEM image of CF composite |

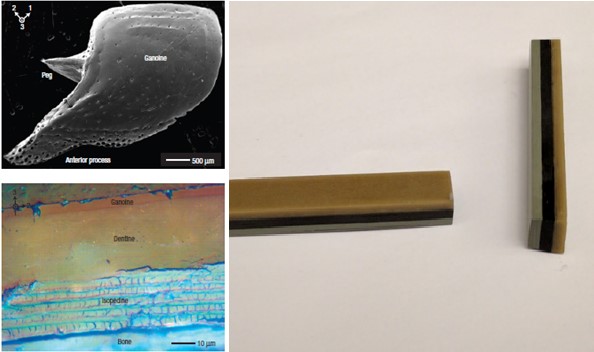

| Design and 3D printing of bioinspired composite materials Inspired by the toughness of the scales of the Polypterus Senegalus, we aim to produce multilayered multimaterial composites through 3D Printing. The aim is to design new inks for Direct Write with different mechanical properties. The superposition of inks with different properties allow for structure with superior resistance to concentrated loads. Y. Abderrafai |

Top left: image of a P. Senegalus Scale Bottom left: SEM image of multilayered structure of the scale Right: 3D Printed multimaterial specimen |

| Fused deposition modelling of piezoelectric sensor with polyvinylidene fluoride(PVDF) and its nanocomposites Piezoelectric sensors are widely used in many applications, but they are subject to the simple shape and complicated physical poling treatment. The objective of this project is to make piezoelectric filament with PVDF nanocomposite filament without high electric field poling and further fabricate piezoelectric sensors with complex shapes by FDM technology. R. Tao |

|

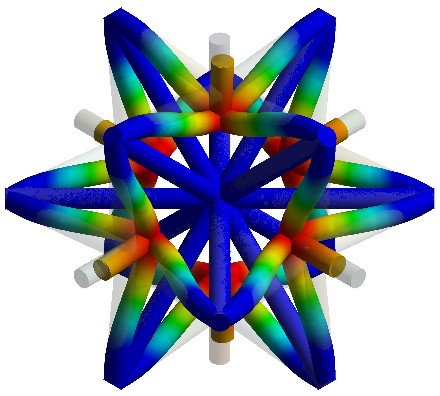

| Failure Analysis and Fabrication Optimization of Microstructured Fibers With Sacrificial Bonds Microstructured fibers with sacrificial bonds fabricated by instability-assisted direct write show similar toughening mechanism as spider silk. In this project, we seek to understand the failure mechanisms of the microstructured fibers through tensile tests and finite element simulations. S. Zou |

Finite element simulation of the bond breaking process in the uniaxial tensile test of microstructured fibers with sacrificial bonds |

| Multinozzle 3D Printing of Composite Materials on Aeronautical Structures 3D printing is a well known rapid-prototyping method. The objective of this research is to push the boundaries by printing a composite Material on a non-planar aeronautical structure with a custom multinozzle print head. J-F. Chauvette |

Simulation of non planar deposition using a 6-axis robot |

| Experimental characterisation and modelling of interfacial behaviour of additively manufactured composite structures The non simultaneous solidification of the composite material filaments extruded during the Fused Deposition Modeling process introduces a local discontinuity where cracks can be initiated. Aim of this project is to empirically investigate the premature failure at the layers interface and to characterize and model the interfacial strength of the filaments. A. Lingua |

Fracture surface of additively manufactured carbon fibre composite (SEM image) |

| Design, manufacturing and test of a high performance and multifunctional Cyr wheel 3D printing of a circus apparatus with high performance and piezoelectric composites. C. Dubost |

|

| Multi-functional 3D-printed lattice structures The objective of this project is to design and manufacture 3D-printed multi-functional meta-lattice structures including bi-material structures with a tunable Poisson’s ratio and coefficient of thermal expansion. H. Y. Sarvestani |

|

| Development of innovative absorbent materials by 3D printing Recently 3D printing expansion allows the fabrication of acoustic absorbers optimized at the microscopic scale. The objective of this project is to use micro-additive manufacturing to create highly absorbent acoustic structures. J. C. Baptista |

pesanreporter.com |

| Conductive surface films or coatings for composite structures This project aims at scaling the production of novel lightning strike protection systems for aircrafts. It will look for promising solutions currently being developed for lightning strike protection with an emphasis on the scalability of those methods. The target is to integrate a protective conductive layer or coating within the manufacturing process of the industrial partner and to scale the process to complete assemblies. D. Brassard |

|

| Additive manufacturing of green conductive thermoplastic polymer composites Since the industry needs are aimed with more green technologies, the design of new functional materials should focus on eco-friendly components. Therefore, the goal of this project is to develop the electrically conductive polymer/carbon nanofiller systems for 3D printing using less hazardous, less toxic, renewable or biodegradable materials. P. Latko-Durałek |

Image from thefabricator.com |

| 3D binder-jetting printing The project involves the additive manufacturing of metallic structures by binder jetting. This technique is using the very fast printing of a polymeric binder to hold small metallic powder together (from a flat powder bed) layer-by-layer. The main challenges addressed in our project is the investigation of different binders-metallic powder systems to obtain a sustainable high performance metallic parts. S. Hosseini Rad |

|

| Additive manufacturing of thermoconductive self-healing polymers The project focusses on developing an intrinsic thermoconductive self-healing polymer that can be printed on the composite laminates as the interlayer. A low power is applied to initiate the in-situ healing of the composite laminate based on the thermal remendability of the polymer. I. L. Hia |

|

| Additive manufacturing of high-performance composites for space application Inspired by bamboo and bones geometry, the objective of this project is to 3D print a strong and light lunar rover structure. PEEK and PEI based composites shows great potential for mechanical and thermal properties, while allowing the possibility to repair a damaged structure. O. Duchesne |

|

| Additive manufacturing of non-planar multifunctional coatings Noise pollution and engine efficiency are two central issues which are regulated through the ICAO’s environmental package. This project addresses said regulations by focusing on the formulation, characterization and printing of a novel lightweight thermoset composite. The new material will be directly deposited as an abradable noise-abating structure onto curved surfaces. D. Brzeski |

Cross section of a printed filament (commercial product, SEM) |

| Single Step 3D Printing of Piezoelectric Devices A new technique is devised to 3D print piezoelectric devices in multi-material components for aerospace, bio-medical and robotics applications. The project involves fabricating a 3D printable piezoelectric nanocomposite with inherent piezoelectric properties and then co-extruding with a commercial silver paint to form readily usable sensors. S. Bodkhe |

|

|

Temperature effects during additive manufacturing of reinforced thermoplastic-based composites by Fused Deposition Modeling (FDM) and their mechanical properties.

|

|

| 3D printing of carbon-reinforced thermoplastic composites by Fused Deposition Modeling (FDM) and their mechanical properties

Reinforced FDM parts can be used for actual applications in aerospace and automotive industries where stronger materials are required to carry higher loads. The objective of this project is to develop a technique to synthesize long and uniform thermoplastic filament reinforced by short carbon fibers. Mechanical testing is performed on coupon and demonstrator parts to evaluate their mechanical performance. H. Mahdavi |

|

| FDM additive manufacturing of high temperature resistant thermoplastic composites for aerospace applications 3D printing allows the fabrication of thermoplastic composite structures with elevated mechanical properties and complex shapes. The objective of this project is to 3D print high performance PEEK and PEI based composite structures featuring improved mechanical, thermal and acoustic properties. F. Iervolino |

3D printing of a PEEK based composite structure |