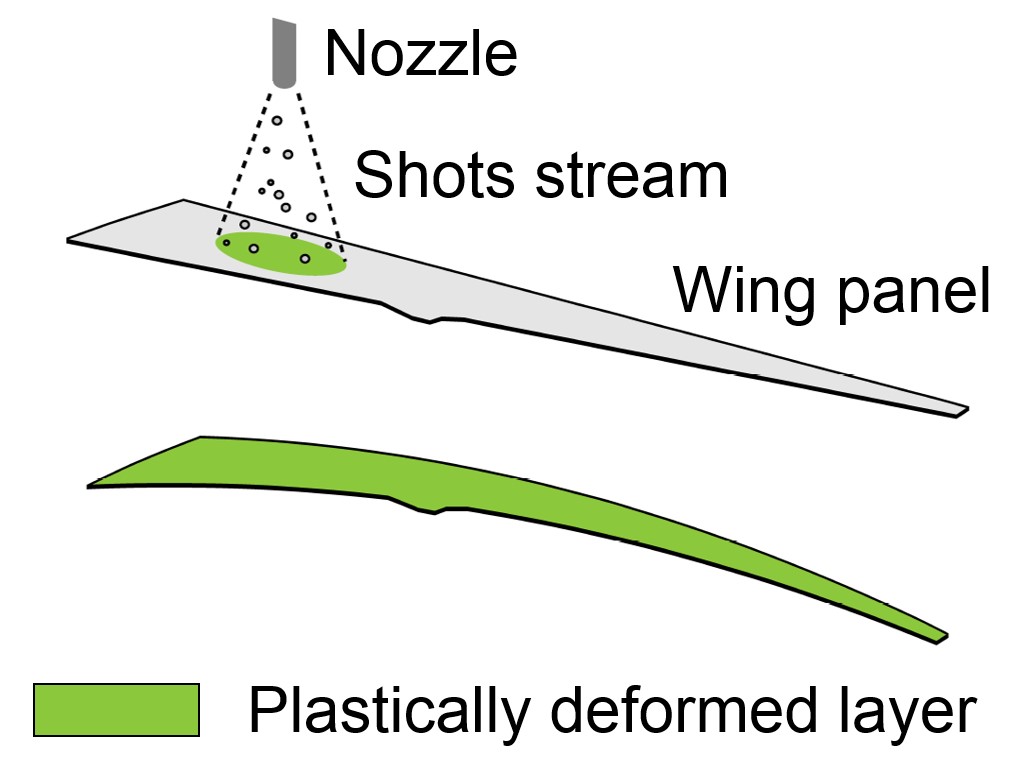

| Simulating conventional peen forming High velocity impacts of small particles onto a thin metallic part induce incompatible plastic strains that in turn cause the part to distort. This effect has been successfully used to shape large industrial parts such as wing panels. This project aims at developing an efficient simulation procedure of the process. It is part of a larger research effort towards integrated simulation and optimization of peen forming. P. Faucheux |

Spanwise forming a wing panel |

| Modeling of shot peen forming using the theory of geometric incompatibilities Shot peen forming is a versatile technique of shaping large thin panels by impacting them with thousands of high-velocity millimeter-sized shots. Two main factors hinder efficiency of this process: the lack of modelling tools and the lack of automation. Our project is intended to fill this gap and to provide industry with an efficient modelling software based on the theoretical framework of incompatible elasticity. V. Sushitskii |

Shots bombarding a metal sheet Source: ceramics.org |

|

Crystal mechanics for shot-peening induced residual stresses and microstructural evolutions prediction Shot-Peening induced intragranular residual stresses and hardening accurate prediction is of utmost importance for fatigue life prediction. The objective of this project is to develop a methodology for SP-induced intra-granular residual stress and hardening prediction in reasonable computation times using crystal plasticity finite elements simulations of a reduced number of shots. The project also focuses on mechanical test at the micrometre scale for constitutive law parameters identification, at high strain rate. S. Breumier |

|

|

Impact of Vibratory Peening on Fatigue life Vibratory Peening (VP) is a modified vibratory finishing process that induces compressive residual stresses comparable to those induced by shot peening, but for a much better surface finish. The process might either yield better fatigue life improvement, which would improve parts performance, or combine peening and finishing steps into a single process, which would improve productivity. The objective of this project is to investigate the effects (roughness, residual stresses, cold work, hardness, microstructural changes, stress relaxation) of Vibratory Peening (VP) on the fatigue lives of titanim alloy and Cemented high strength steel. K. Chouchane and M. Paques |

Vibratory Peening Machine |

|

Development of shot peening robot for Experimental and Finite Element study The objective of this project is to develop a small scale shot peening robot to study the shot peening process and compare it with industrial shot peening machine. It also includes development of finite element code for peen forming and cross verifying the computational results with experiment. T. Deshmukh |

|

| Analytical fatigue life prediction of shot peened 300M steel The shot peening process involves bombarding of a ductile metal surface with high velocity particles (or shots) to generate compressive residual stresses which arrests/delays the propagation of short fatigue cracks, thereby increasing the life of treated metal parts. The research project aims at developing an analytical model to predict the effects of shot peening on the fatigue life of 300M steel, which is extensively used in manufacturing aircraft landing gears. A. Bag |

|

| Analytical fatigue life prediction for shot peened AA7050 Shot peening consists of projecting high velocity particles onto metallic surfaces. The main goal is to increase fatigue life of structure through the introduction of compressive residual stress, hardening, and grain distortion. However, shot peening is not reliable enough to use as its maximal potential. The overall goal of the project is the development of an analytical model able to predict fatigue life, with a high level of reliability, for shot peened laboratory specimens of aluminum alloy 7050. C. Bianchetti |

|

| Vibratory peening for the fatigue life improvement of aerospace parts Vibratory peening is a finishing process that induces compressive residuals stress in a sub-surface layer and that shows really good surface finish. These two aspects are factors of fatigue life improvement. It consists in diving a part in a tub filled with steel shots and producing vibrations that are inducing impacts between shots and part. L.Canals |

|

|

Analytical fatigue life prediction of shot peened Inconel 718 Inconel 718 gas engine components are submitted to fatigue loads. Shot peening, a cold work process consisting in projecting high velocity particles onto a ductile metallic part, is used to improve their fatigue life. The aim of this project is to develop a model that analytically predicts fatigue cracks initiation and propagation in shot peened Inconel 718 with the final objective of predicting fatigue life. T. Klotz |

|