The laboratory is located in the main building room C-543 and C-545. The laboratory is located in the main building room C-543 and C-545. |

Several recent dual-screen workstations are available in the laboratory. Each one is installed with an up to date Windows 10 OS. A complete suite of softwares are installed allowing for the analysis and design of robotic systems: Matlab, Simulink, Labview, Ansys, Catia, LaTeX, etc.

A real-time control architecture is available in the laboratory. This system, by Opal-RT, is able to control up to 64 axes simultaneously and in real-time (approximately 10 standard robots). Using a dedicated software, RT-Lab, integrated with Simulink and using the QNX operating system, one can design and implement real-time algorithms with minimal effort.

A real-time control architecture is available in the laboratory. This system, by Opal-RT, is able to control up to 64 axes simultaneously and in real-time (approximately 10 standard robots). Using a dedicated software, RT-Lab, integrated with Simulink and using the QNX operating system, one can design and implement real-time algorithms with minimal effort.

More than fifty electrical actuators (both DC and steppers) of all sizes and powers are available in the laboratory. Power amplifiers and drivers have also been purchased to control these motors. Most of the latter are from Maxon Motors, the well-known motor manufacturer who built the actuators that equip the rovers on Mars.

More than fifty electrical actuators (both DC and steppers) of all sizes and powers are available in the laboratory. Power amplifiers and drivers have also been purchased to control these motors. Most of the latter are from Maxon Motors, the well-known motor manufacturer who built the actuators that equip the rovers on Mars.

Several six-axis force sensors from ATI Industrial Automation with different sizes and ranges are available.

Several six-axis force sensors from ATI Industrial Automation with different sizes and ranges are available.

The laboratory is equipped with all the instruments necessary to prototype and test custom electronic cards: function generator, digital oscilloscope (USB), regulated power supply, precision multimeter, digital iron, etc. Most of these equipments have been purchased from Agilent.

The laboratory is equipped with all the instruments necessary to prototype and test custom electronic cards: function generator, digital oscilloscope (USB), regulated power supply, precision multimeter, digital iron, etc. Most of these equipments have been purchased from Agilent.

Our laboratory owns a Z450 rapid prototyping machine from ZCorp as well as an SST 1200es machine from Dimension.

Z450 by ZCorp

This machine allows us to print in color and three dimensions mechanical parts with arbitrary shapes at low costs. It is based on a technology developed by the MIT where a printhead deposits a binder onto a composite powder where the part will be solid.

Then, another layer of powder is put on top of the previous one and the machine repeats the same procedure. Once the part is completely done with the binder, excess powder is removed. Finally, the part is infiltrated with a chemical (cyanoacrylate, epoxy, salted water) giving the part its final mechanical properties and strength.

The machine is available for any user from Polytechnique. Please contact us for an estimate of the cost.

Examples of parts built using a Z450 (all these images are from the ZCorp website where high resolution files are available). Please note that the colors are created by the machine itself and not painted afterwards:

SST 1200es by Dimension

This machine is based on the Fused Deposition Modeling (FDM) technology which consists in laying on the workplate a melted plastic thread (ABS) and using the latter to draw the shape of the object to be built. Once this first slice is done, the workplate is slightly lowered an another slice is drawn. In most case a support material is needed to serve as a fundation to subsequent slices. This support material is automatically laid by the machine and removed once the building proces is complete by immerging the part in a special bath that melts the support material but leaves the original part unmodified.

The machine is available for any user from Polytechnique. Please contact us for an estimate of the cost.

Note to external clients: the machines available at Polytechnique Montréal are used for educational and research purposes only. They cannot be used to compete with the private sector. If no companies can build your parts we might accept an external contract but only as a last resort. Consequently, our prices are *not* competitive by any means and we must charge a lot more that any other private company.

The laboratory purchased several robots:

| Collaborative Baxter robot with its electric grippers | ||

|

||

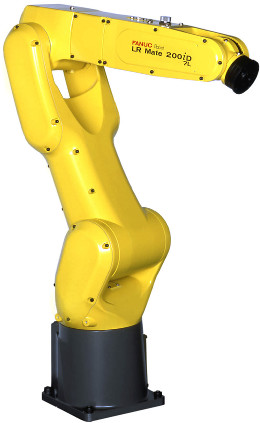

| An industrial serial robot FANUC LR Mate 200iD/7L (long arm version) with its R-30i controller | ||

|

||

| Two mobile robots Khepera II including several optional turrets (e.g. linear vision, gripper, etc.) | ||

|

A Falcon Limited Edition haptic device from Novint is available in the laboratory. It is a parallel robot, namely the famous Delta, with three degrees of freedom allowing to exert forces on the user. Therefore, one can control an arbitrary system while feeling characteristics such as stiffness, viscosity or rugosity. The Software Develpment Kit (SDK) is also available in the laboratory enabling us to use the falcon for dedicated purposes.

A Falcon Limited Edition haptic device from Novint is available in the laboratory. It is a parallel robot, namely the famous Delta, with three degrees of freedom allowing to exert forces on the user. Therefore, one can control an arbitrary system while feeling characteristics such as stiffness, viscosity or rugosity. The Software Develpment Kit (SDK) is also available in the laboratory enabling us to use the falcon for dedicated purposes.